The unmistakable sound of a diesel engine has long been the soundtrack to American industry and adventure. For decades, it has represented uncompromising capability. Yet, with rising maintenance costs and complex emissions systems, many prospective buyers are asking a critical question: does the power of a diesel still justify the price of admission? The answer is not as simple as it once was, and it requires a clear-eyed look at what these trucks do best and what they demand in return.

The Enduring Appeal of Diesel Power

To understand why drivers continue to pay a premium for diesel, you have to grasp the fundamental difference between torque and horsepower. Think of horsepower as a sprinter, delivering explosive speed for a short burst. Torque, on the other hand, is a powerlifter, providing immense, sustained strength to move heavy objects without breaking a sweat. A gasoline engine can have high horsepower, but it’s the diesel’s massive torque, delivered at low RPMs, that defines its character.

This isn’t just a technical detail. It’s the feeling of confidence you get when pulling a 15,000-pound fifth-wheel trailer up a steep grade in the Rocky Mountains. While a gasoline engine would be screaming at 5,000 RPM, the diesel just digs in, holding its gear and pulling the load with a steady, reassuring rumble. It’s a level of effortless capability that gas engines still struggle to replicate under serious strain. This is the core reason people choose diesel. It’s not for commuting; it’s for working.

This capability is built on a foundation of engineered longevity. Diesel engines are constructed with materials like compacted graphite iron blocks and forged internal components, designed to withstand immense compression and stress. It’s why seeing a diesel truck with 500,000 miles on the odometer isn’t a surprise. For a business owner or a serious hobbyist, this transforms the purchase from a simple vehicle into a long-term capital investment. You’re buying a tool designed to last for decades, not just a few years. For those interested in a broader look at the market, our comprehensive guide to trucks offers a great starting point.

Beyond the mechanical advantages, there are psychological benefits, especially for those who cover long distances. The superior highway fuel efficiency of a diesel means fewer fuel stops, which translates to less time wasted and lower operational fatigue on a cross-country haul. You can drive for hundreds of miles without the nagging thought of finding the next gas station. It’s this combination of raw power, engineered durability, and long-haul comfort that continues to make diesel the undisputed king for those who demand the most from their vehicle.

The Reality of Modern Diesel Maintenance

The confidence that comes from diesel power has a clear and consistent price tag attached. While the initial purchase price is higher, the real financial commitment reveals itself over years of ownership. The conversation about the diesel truck ownership cost must move beyond the showroom floor and into the service bay, where the differences become stark.

Routine Service: More Than Just an Oil Change

Even basic maintenance on a modern diesel is a more involved and expensive affair. We’ve all felt that slight sting at the register for a standard oil change, but for a diesel owner, it’s a different scale. A typical gasoline V8 might take six to eight quarts of oil. A modern diesel truck requires 12 to 15 quarts of specialized, more expensive CJ-4 or CK-4 specification oil designed to handle soot and high compression. That alone can double or triple the cost of a simple service. Then there are the fuel filters. Diesels use two of them, and they need to be changed far more frequently than on a gas engine to protect the highly sensitive fuel system. Ignoring this is not an option if you want to avoid catastrophic repair bills down the road.

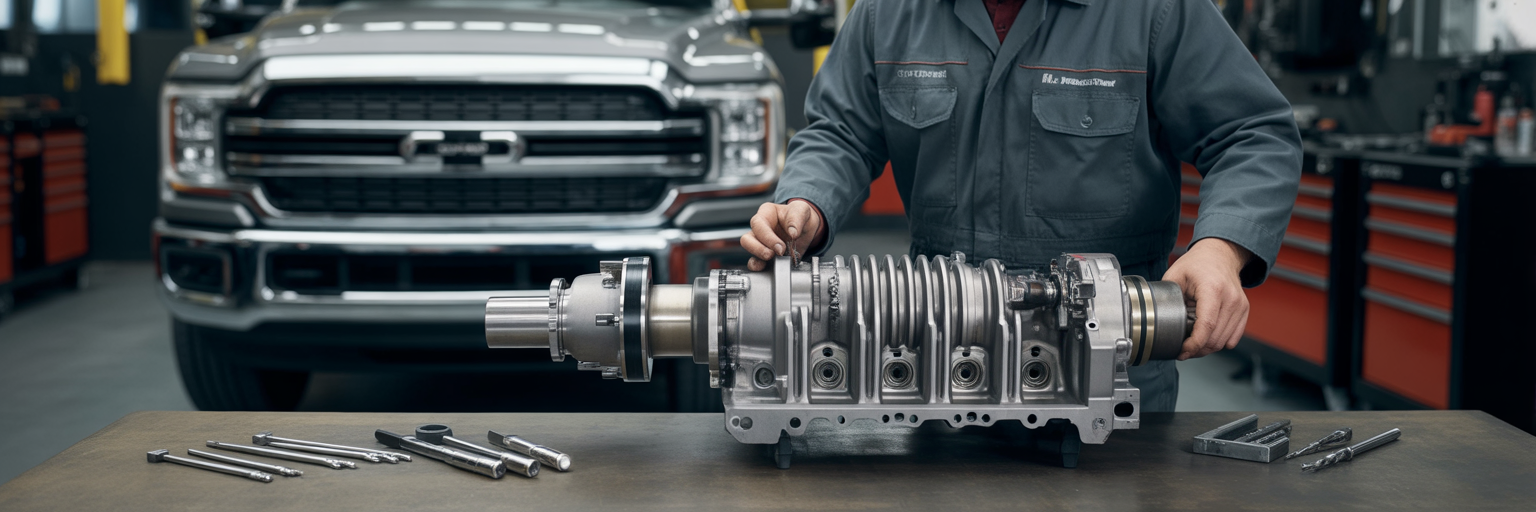

The High Cost of Precision Components

The components that give a diesel its incredible power and efficiency are marvels of engineering, operating under immense pressure. This precision comes at a cost when they fail. The high-pressure fuel system, particularly the CP4 injection pump found in many models, is a known weak point. When it fails, it can send metal shavings throughout the entire fuel system, requiring a full replacement of the pump, injectors, and fuel lines. This single repair can easily cost thousands of dollars. Fuel injectors themselves are also expensive, precision-machined parts that can cost several hundred dollars each to replace. These aren’t rare occurrences; they are known failure points that prospective owners must budget for.

Finding the Right Mechanic: The Specialist Tax

You can’t take a 2026 diesel truck to just any corner garage. These vehicles are packed with complex electronics and require specialized diagnostic tools that most independent shops don’t own. This means you’re often tied to the dealership or a certified diesel specialist, both of which typically charge higher labor rates. This “specialist tax” applies to everything from diagnosing an engine code to performing major repairs. While some owners can handle basic tasks, a comprehensive diesel engine maintenance guide would be incomplete without stressing that most jobs require a professional. For those who do tackle their own work, our DIY section can help distinguish between a manageable task and a job for the experts.

To put this in perspective, analysis from Truck Report Geeks suggests that diesel maintenance can average around $6,800 over a five-year period, not including tires or major unexpected failures. Here’s a quick breakdown of common costs:

- Oil Change (12-15 quarts): $120 – $200

- Fuel Filter Replacement (both): $150 – $300

- DEF System Sensor Replacement: $500 – $1,000

- Single Fuel Injector Replacement: $600 – $1,200+

- DPF Cleaning or Replacement: $1,500 – $5,000+

Decoding Complex Emissions Systems

Perhaps the most misunderstood and frustrating aspect of modern diesel ownership revolves around the emissions control systems. Mandated by federal regulations, these systems are essential for making diesels run clean, but they also introduce a new layer of complexity and potential failure points. Understanding them is not optional; it’s critical to avoiding costly downtime. According to a white paper from the International Council on Clean Transportation (ICCT), these technologies are a direct result of increasingly strict standards, making them an unavoidable part of the modern diesel experience.

The Alphabet Soup: DPF, SCR, and DEF Explained

It’s easy to get lost in the acronyms, but the concepts are straightforward. Think of the Diesel Particulate Filter (DPF) as a sophisticated, self-cleaning furnace filter for your exhaust. It traps soot and particulate matter. The Selective Catalytic Reduction (SCR) system works with Diesel Exhaust Fluid (DEF) to neutralize harmful nitrogen oxides (NOx). You can imagine the SCR system as a purifier that injects DEF, a urea-based solution, into the hot exhaust stream, where it chemically converts NOx into harmless nitrogen and water. Together, these components make a modern diesel run dramatically cleaner than its predecessors.

Common Failure Points and Their Symptoms

The biggest challenge with these systems is that their health is directly tied to how you drive. The DPF needs to get extremely hot to burn off the trapped soot in a process called “regeneration.” This requires sustained highway speeds. If a truck is used primarily for short, low-speed city trips, the DPF can become clogged. The first sign is usually a warning light on the dash, but if ignored, it can force the truck into “limp mode,” drastically reducing power and forcing a trip to the dealer for a manual regeneration or even a costly replacement. These are some of the most common modern diesel emissions problems.

The SCR system has its own set of issues. DEF can freeze in cold climates, so the system includes heaters that can fail. The sensors that monitor NOx levels and DEF quality are also notoriously sensitive. A failure in any of these components can trigger a countdown on your dashboard, warning you that the truck will refuse to start after a certain number of miles if the issue isn’t fixed.

The Financial Risk of Emissions Repairs

When these systems fail, the repairs are not cheap and rarely optional. A faulty DEF sensor or heater can cost between $1,000 and $3,000 to replace. A clogged DPF that cannot be manually cleaned may require a full replacement, a job that can run upwards of $5,000. Because these systems are federally mandated, you cannot legally remove them, and the truck will not pass inspection without them. The most actionable takeaway for any potential owner is this: your driving habits will determine the health of your emissions system. A truck that regularly tows and sees consistent highway miles will likely have few issues. A truck that sits in city traffic and rarely gets up to speed is a prime candidate for expensive emissions-related repairs.

Calculating the True Cost of Fuel

For years, the simple math for diesel was straightforward: you paid more per gallon but went farther on each one. In 2026, with fuel prices fluctuating, the calculation is more nuanced. A smart buyer needs to look beyond the price at the pump and calculate their personal break-even point. The higher diesel truck ownership cost upfront only makes sense if you save money in the long run.

Let’s run the numbers. With projected 2026 prices hovering around $4.35 per gallon for both diesel and gasoline, the advantage shifts entirely to efficiency. A modern diesel heavy-duty truck might average around 22 MPG on the highway, while its gasoline counterpart could be closer to 16 MPG. This difference seems small on paper, but it compounds quickly with mileage. For those exploring which models lead in this area, our detailed comparison of 2025 trucks provides further insights.

The table below illustrates how annual mileage dramatically changes the fuel cost equation. A low-mileage owner may never see a return on their investment, while a high-mileage hauler will realize substantial savings.

Annual Fuel Cost Comparison: Diesel vs. Gasoline Truck (2026 Estimates)

| Annual Miles Driven | Estimated Annual Fuel Cost (Diesel) | Estimated Annual Fuel Cost (Gasoline) | Potential Annual Savings with Diesel |

|---|---|---|---|

| 12,000 miles | $2,372 | $3,262 | $890 |

| 25,000 miles | $4,943 | $6,797 | $1,854 |

| 50,000 miles | $9,886 | $13,594 | $3,708 |

Note: Calculations are based on projected 2026 fuel prices of $4.35/gallon for both diesel and gasoline. Assumed fuel efficiency is 22 MPG for the diesel truck and 16 MPG for a comparable heavy-duty gasoline truck. These figures are illustrative and will vary based on driving style, load, and local fuel prices.

As the data shows, the financial argument for diesel is weak for someone driving 12,000 miles a year, mostly commuting. The $890 in annual fuel savings is unlikely to offset the higher maintenance costs and initial purchase price. However, for a contractor or RVer driving 50,000 miles a year, the nearly $4,000 in annual savings becomes a significant factor that can easily justify the diesel premium. It’s also important to briefly mention fuel quality. Using high-quality diesel and, in some cases, fuel additives is cheap insurance to protect the sensitive and expensive high-pressure fuel systems discussed earlier. Ultimately, the decision comes down to your personal use case. You must honestly assess your annual mileage and how much of it will be spent towing to determine if the math works in your favor.

Long-Term Value and Resale Potential

After confronting the high costs of maintenance and fuel, it’s easy to question a diesel’s worth. However, the financial story has a powerful final chapter: depreciation. While a diesel truck demands more money to buy and maintain, it holds its value with a tenacity that few other vehicles can match. This exceptional diesel truck resale value is the great equalizer in the total cost of ownership equation.

It’s a well-known phenomenon in the used vehicle market. A five-year-old diesel truck can often retain 70-75% of its original sticker price, a figure that is nearly unheard of in the automotive world. This isn’t just luck; it’s driven by simple supply and demand. The durability and towing capability that make diesels desirable when new are the exact same qualities that make them highly sought after on the second-hand market. Buyers know that a diesel engine is built for the long haul.

This directly connects to the engine’s engineered longevity. There’s a common saying among diesel enthusiasts that an engine is “just getting broken in” at 100,000 miles. While a gasoline truck with that mileage might be seen as approaching the end of its reliable life, a well-maintained diesel is viewed as having hundreds of thousands of miles of service left. This perception makes a used diesel a far more attractive and confidence-inspiring purchase, which keeps demand and prices high. The reputation of different manufacturers also plays a role, and when considering a purchase, exploring the various brands and their reliability track records is a crucial step.

Of course, this high resale value isn’t guaranteed. It depends on the owner. To maximize your return when it’s time to sell, you must be diligent. Here are four key actions:

- Keep meticulous service records. A thick folder of receipts from a reputable shop is the best proof of a well-cared-for truck.

- Use high-quality OEM or equivalent parts. Buyers are wary of cheap, aftermarket parts on critical components.

- Maintain the cosmetic condition. A clean interior and rust-free body show that the truck was cared for, not just used.

- Avoid irreversible modifications. While some upgrades are fine, extreme engine tunes or suspension lifts can shrink your pool of potential buyers.

When you compare this to a heavy-duty gasoline truck, the picture becomes clear. The gas truck is cheaper to buy, but its value drops much faster. Over a 5-to-10-year ownership period, the slower depreciation of the diesel can significantly close, or even erase, the initial cost gap.

The Shifting Competitive Landscape

A decade ago, the choice for serious towing was simple: you bought a diesel. Today, the market is more crowded, and buyers have compelling alternatives. Evaluating a diesel in 2026 means honestly assessing it against a new generation of gasoline, electric, and hybrid competitors. The question of diesel vs gas truck 2026 is more complex than ever.

The Challenge from Advanced Gasoline Engines

Gasoline heavy-duty trucks are no longer the underpowered options they once were. Automakers have responded to the market with large-displacement V8s and even turbocharged V6s that produce impressive horsepower and torque figures. Their primary advantages are a lower purchase price by several thousand dollars and significantly cheaper routine maintenance. However, their fundamental weakness remains: fuel efficiency under load. Hook up a 10,000-pound trailer, and that gas V8’s fuel economy will plummet into the single digits. They also tend to struggle more at high altitudes, where the thinner air robs naturally aspirated engines of power, forcing them to work much harder than their turbocharged diesel counterparts.

Electric Pickups: A Different Tool for a Different Job

Electric trucks have arrived with headline-grabbing acceleration and impressive payload capacities. For daily driving, local work, and light-duty tasks, they are a fantastic option with extremely low “fuel” and maintenance costs. However, for the core diesel buyer, they currently fall short in one critical area: towing range. An EV truck that boasts a 300-mile range can see that figure cut by more than half when pulling a heavy trailer. This turns a 500-mile journey into a logistical nightmare of frequent, lengthy charging stops. Until battery technology and charging infrastructure make significant leaps, electric pickups remain a different tool for a different job, not a true replacement for a long-haul diesel.

The Hybrid Middle Ground

Hybrid systems, like Ford’s PowerBoost, represent a compelling middle ground. They combine a gasoline engine with an electric motor to offer improved city fuel economy and incredibly useful features like Pro Power Onboard, which turns the truck into a mobile generator. They are a great choice for contractors or recreational users who need power on a job site or campsite. However, they still don’t replicate a diesel’s effortless highway towing efficiency over long distances. The rise of these alternative powertrains is an industry-wide trend, and it’s interesting to see how electrification is also impacting other segments, like the growing popularity of the best hybrid SUVs under $35k.

Looking further ahead, some manufacturers are exploring hydrogen for the heaviest commercial trucks, but for a consumer pickup purchase in 2026, it remains a distant technology. For now, the choice is between diesel, gas, hybrid, and electric, each with a distinct set of strengths and weaknesses.

Future-Proofing Your Diesel Investment

Making the right decision in 2026 means synthesizing all these factors: the unmatched power, the demanding maintenance, the complex emissions systems, and the strong resale value. For the right owner, a diesel truck remains an invaluable tool. For the wrong one, it can become a financial burden. Future-proofing your investment, whether you’re buying new or used, comes down to your mindset and your habits.

Adopt a Proactive Maintenance Mindset

You cannot afford to be reactive with a modern diesel. The best way to prevent premature and costly failures is to follow the manufacturer’s “severe duty” maintenance schedule, even if you feel your usage is “normal.” This means more frequent oil changes, fuel filter swaps, and fluid checks. It’s a small price to pay to protect a massive investment. Staying informed is also key; keeping an eye on our news section for updates on things like the recent GM 6.2L engine recall helps you stay ahead of potential issues.

The Dangers of ‘Deleting’: A Risky Gamble in 2026

In online forums, you’ll inevitably find talk of “deleting” the emissions equipment (DPF, SCR, EGR) to simplify the truck and supposedly improve reliability. In 2026, this is a fool’s errand. The EPA has cracked down hard, with fines that can reach tens of thousands of dollars for both the owner and the shop that performs the work. It will instantly void any remaining warranty, make the truck unsellable in many states, and can even create new mechanical problems if not tuned correctly. We stand firm in our belief that this is a risk not worth taking.

The Ideal Diesel Owner Profile: Is This You?

To ensure your truck remains a healthy, valuable asset, a few practical habits are essential. These simple steps can save you thousands in the long run.

- Give it a weekly highway run. Ensure the truck gets at least 20-30 minutes at sustained highway speed once a week. This is the single best thing you can do to allow the DPF to complete its regeneration cycle and stay clean.

- Use high-quality DEF. Only use API-certified DEF from sealed containers. Cheap or contaminated DEF can crystallize and destroy expensive sensors and pumps.

- Respect warm-up and cool-down. Allow the engine to warm up for a few minutes before driving off and let it idle for a minute or two after towing or a hard run. This allows oil to circulate and protects the turbocharger from heat-related damage.

So, who is the ideal diesel owner in 2026? It’s someone who consistently tows or hauls heavy loads over significant distances. It’s someone who is financially prepared for the higher maintenance commitment and has budgeted for potential five-figure repairs. And it’s someone who plans to keep the truck long enough to benefit from its legendary durability and strong resale value. If you don’t fit that profile, a modern gasoline or hybrid truck is likely a more practical and economical choice for your needs.